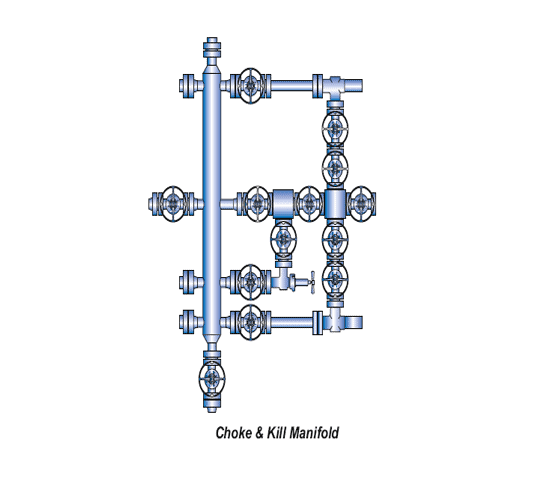

PARVEEN fabricates custom designed choke and kill manifold :

1) In oil/gas well drilling operation, drilling fluids (Muds) of designed gravity are used to overcome sub-surface pressure or the influx of formation fluid. On some occasion, kicks are experienced with change of pressure of formation while drilling. This is necessary to build up drilling fluid density to prevent influx of formation fluid. The Choke and Kill Manifold allows the driller to regulate back-pressure on the formation while gradually density of the drilling fluid is built up by circulation with closed B.O.P., till the well is stabilized and drilling is resumed.

The Choke and Kill Manifold are available up to 10,000 PSI in sizes of 2” to 3” for standard and sour services. Other type of Manifold (stand pipe, cementing etc.) can also be made available.

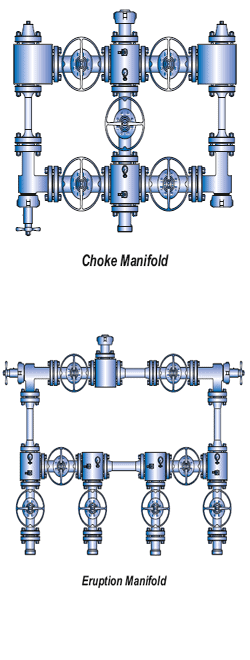

2) For well Testing / Completion / Intervention, Industry uses varies configuration of Manifold, as per requirement of Service / Operating Companies, PARVEEN designs and fabricates custom made manifold in sizes of 2” to 3” up to 10,000 PSI for standard and sour services for following application.

(a) Choke Manifold For flow back/work over

(b) Production Manifold for diverting flow through test separator or vent or burner.

(c) Gas Manifold for Diverting gas through orifice meter or burner.

(d) Data Recorder for recording flowing pressure and temperature.

(e) Stimulation / Treatment for Well stimulation/treatment service.