Assembly Instructions:

Reference: Model Fury 05 Hydraulic Setting Tool Parts List.

Drift Cylinder (item 6) with Piston (item 7). Install all O-Rings. Lubricate all O-Rings, Threads, Sealing and Sliding Surfaces with Mobil Grease HP. Wrench only where indicated. File away wrench marks. Note: Never use pipe wrench or vise on Cylinder (item 6) at midpoint. Make Cylinders (item 6) strap wrench tight by locating strap on knurled area of cylinder. Spanner wrench tight means hand tight then striking spanner handle with rubber mallet two or three times.

Screwdriver tight means hand tight with a medium blade 6” long screwdriver.

1. Place Top Sub (item 2) in vise at box connection. Slide Cylinder Cap (item 4) on Top Sub. Install (2) Brass Shear Screws (item 3) in flat bottom holes screwdriver tight then back-off 1/8 turn.

2. Screw first Piston (item 7) in Top Sub wrench tight. Lubricate entire ID of first Cylinder (item 6) with Mobil Grease HP. Slide Cylinder (item 6) over Piston and screw to Cylinder Cap (item 4). Make strap wrench tight. Screw first Upper Connector (item 9) in Cylinder and make spanner wrench tight.

3. Screw second Piston (item 7) in previous Piston wrench tight. Lubricate entire ID of second Cylinder (item 6) with Mobil Grease HP. Slide Cylinder (item 6) over Piston and screw to Upper Connector (item 9). Make strap wrench tight. Screw second Upper Connector (item 9) in Cylinder and make spanner wrench tight.

4. Screw third Piston (item 7) in previous Piston wrench tight. Lubricate entire ID of third Cylinder (item 6) with Mobil Grease HP. Slide Cylinder (item 6) over Piston and screw to Upper Connector (item 9). Make strap wrench tight. Screw Lower Connector (item 10) in Cylinder and make spanner wrench tight. Note: The Lower Connector (item 10) differs from the Upper Connector (item 9) with a flat bottom spot face in the lower thread and the OD is knurled.

5. Slide upper end of Ball Seat Housing (item 13) through Lower Connector (item 10) then screw to lower end of previous Piston wrench tight. Wrench at knurled area on Ball Seat Housing.

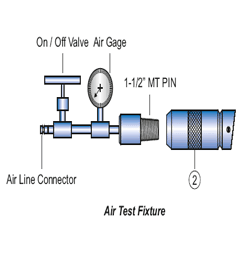

6. Internally test 3-hydraulic chambers with air to check for cut or missing o-rings. Temporally install solid ball seat (item 23) in lower end of Ball Seat Housing (item 13). Screw Bottom Adapter Sub (item 18) on Ball Seat Housing (item 13) wrench tight. Wrench at knurled area on Ball Seat Housing. Make sure Top Sub (item 2) is secure in pipe vise, tighten both brass shear screws (item 3) then connect air test fixture. Make 1-1/4” MT connection wrench tight and close on/off valve. Connect airline, open on/off valve and allow air to fill HST, then close valve. If gage is steady for 2-minutes and no flow of air can be heard then HST is tested. If a steady air test cannot be achieved then HST must be disassembled to find the cause. Bleed air pressure to zero and remove Bottom Adapter Sub (item 18) by placing a back up at knurled area on Ball Seat Housing. Remove Solid Ball Seat (item 23). Install Ball Seat (item 17) in lower end of Ball Seat Housing (item 13). Screw Bottom Adapter Sub (item 18) on Ball Seat Housing (item 13) wrench tight. Install Socket Head Set Screw (item 15).

7. If the desire is to run HST with a solid seat “no ball” then install Optional Solid Seat (item 23) in lower end of Ball Seat Housing.

8. Screw Push Sleeve (item 12) to Lower Connector (item 10). Make spanner wrench tight. Install (1) Socket Head Set Screw (item 11).

9. Screw Bottom Adapter Sleeve (item 19) to Push Sleeve (item 12). Make spanner wrench tight. Install (1) Socket Head Set Screw (item 11). Install (2) Socket Head Set Screws (item 20) in Bottom Adapter Sleeve (item 19).

10. Re-tighten Brass Shear Screws (item 3). Connect airline, open on/off valve and allow air to flow through HST to ensure the internal flow path is free and clear (no ball is in place). File away all wrench marks. Remove air test fixture.

Disassembly Instructions:

1. Drain all well fluids from Hydraulic Setting Tool and dispose off properly. Place Top Sub (item 2) in pipe vise and close setting stroke gap between Top Sub (item 2) and Cylinder Cap (item 4) by pushing outer components upward towards pipe vise. Keep hands clear of this area during procedure.

2. Disassembly is basically the reverse operation of the assembly with the exception of the Pistons (item 7), Cylinders (item 6) and Connectors (item 9 & 10). Occasionally these items break at locations other than intended. If this occurs remove Lower Connector and slide down enough to place a wrench on the previous pistons knurled area.

3. Visually inspect each component for wear especially the Ball Seat area. Remove all o-rings and discard properly. Clean all parts thoroughly then re-assemble Hydraulic Setting Tool complete with new o-rings. Label outside of Hydraulic Setting Tool with the description, part number, ball size and type o-ring kit.

Operational Procedure:

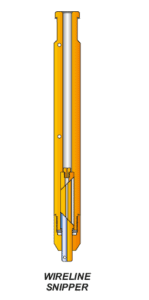

1. Run the Model Fury 10 Hydraulic Setting Tool and BP/CR several feet below the setting depth. Note: The Fury circulation ports are located below the ball seat. These ports will allow the tubing to fill going in the hole or for circulating a maximum rate of 1/4 BPM while going in the hole. Well fluid must clean and free of debris (sand) for the HST to work properly. Warning: The setting sequence will begin at 1,250 psi differential pressure in the tubing “at the tool” (see step 4).

2. Pick up slowly to setting depth to remove slack from tubing string.

3. Drop a 1/2” diameter brass ball and slowly pump down until it has seated (pressure increase).

4. Slowly pressure workstring to establish a 1,250 psi (1,750 psi max) differential pressure inside the tubing “at the tool” to begin the setting sequence.

5. Continue pressuring workstring to establish a 2,500 psi differential pressure inside the tubing “at the tool” to anchor the BP/CR against the casing wall. Pick up tubing to the neutral position. Hold pressure for 5 minutes.

6. Continue pressuring workstring to establish a 3,200 psi (3,700 psi max) differential pressure inside the tubing “at the tool” to complete the set. Pick up on tubing to determine if disconnected from BP/CR. If the HST has not disconnected from BP/CR then pick up 1,000 pounds over tubing weight and pressure workstring again to establish 3,200 psi (3,700 psi max) inside the tubing “at the tool” to complete set. Over pressuring HST will cause damage to tool.

7. Apply 1,000 pounds of set down weight to determine if BP/CR is securely set.

8. The Fury 10 HST will automatically dump pressure when fully stroked out. Clean and re-dress Hydraulic Setting Tool and Setting Adapter Kit.

Troubleshooting:

Condition: HST does not disconnect from BP/CR.

Pull 1,000 pounds over tubing weight and pressure workstring again to establish a 3,200 psi (3,700 psi max) inside the tubing “at the tool” to disconnect from BP/CR.

If unsuccessful, then bleed off pressure, return tubing to the neutral point and reverse circulate capacity of the tubing (+10 BBL) to remove debris that may be inside the tubing and tool. Circulate Ball back to the Ball Seat then pull 1,000 pounds over tubing weight and pressure work string again to establish a 3,200 psi (3,700 psi max) inside the tubing “at the tool” to disconnect from BP/CR.

If unsuccessful, then bleed off pressure and pull 30,000 pounds over tubing weight to disconnect from BP/CR. Over pressuring HST will cause damage to tool.