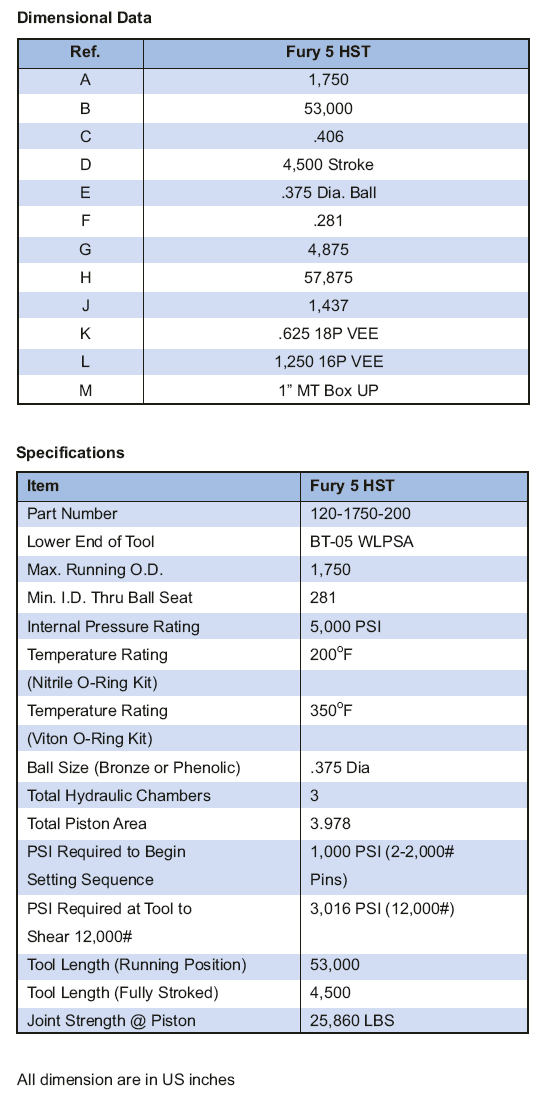

Operational Procedure:

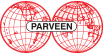

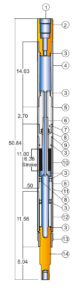

1. Run the Model Fury 05 Hydraulic Setting Tool and BP/CR several feet below the setting depth. Note: The Fury circulation ports are located below the ball seat. These ports will allow the tubing to fill going in the hole or for circulating a maximum rate of ¼ BPM while going in the hole. Well fluid must clean and free of debris (sand) for the HST to work properly. Warning: The setting sequence will begin at 1,000 psi differential pressure in the tubing “at the tool” (see step 4).

2. Pick up slowly to setting depth to remove slack from tubing string.

3. Drop a 3/8” diameter brass ball and slowly pump down until it has seated (pressure increase).

4. Slowly pressure workstring to establish a 1,000 psi (1,500 psi max) differential pressure inside the tubing “at the tool” to begin the setting sequence.

5. Continue pressuring workstring to establish a 2,500 psi differential pressure inside the tubing “at the tool” to anchor the BP/CR against the casing wall. Pick up tubing to the neutral position. Hold pressure for 5 minutes.

6. Continue pressuring workstring to establish a 3,100 psi (3,600 psi max) differential pressure inside the tubing “at the

tool” to complete the set. Pick up on tubing to determine if disconnected from BP/CR. If the HST has not disconnected from BP/CR then pick up 1,000 pounds over tubing weight and pressure workstring again to establish 3,100 psi (3,600 psi max) inside the tubing “at the tool” to complete set. Over pressuring HST will cause damage to tool.

7. Apply 1,000 pounds of set down weight to determine if BP/CR is securely set.

8. The Fury 5 HST will automatically dump pressure when fully stroked out. Clean and re-dress Hydraulic Setting Tool and Setting Adapter Kit.

Troubleshooting:

CONDITION: HST does not disconnect from BP/CR

Pull 1,000 pounds over tubing weight and pressure workstring again to establish a 3,100 psi (3,600 psi max) inside the tubing “at the tool” to disconnect from BP/CR.

If unsuccessful, then bleed off pressure, return tubing to the neutral point and reverse circulate capacity of the tubing (+10 BBL) to remove debris that may be inside the tubing and tool. Circulate Ball back to the Ball Seat then pull 1,000 pounds over tubing weight and pressure workstring again to establish a 3,100 psi (3,600 psi max) inside the tubing “at the tool” to disconnect from BP/CR. If unsuccessful, then bleed off pressure and pull 12,000 pounds over tubing weight to disconnect from BP/CR. Over pressuring HST will cause damage to tool.