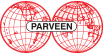

PARVEEN 1″ & 1- 1/2″ OD wireline retrievable injection gas lift super flow orifice valves are used for continuous flow application. These are designed for circulating operations and provide a means of flow from casing to annulus through orifice and then into the tubing.

OPERATION

Super flow orifice valve utilizes an orifice venturi as well as a back check valve for continuous flow operations. Injection fluid enters through the entry ports and then flows through orifice venturi. Injection pressure moves the back check valve off the seat & thus allowing fluids to enter into the tubing. Reverse flow pushes the check valve on seat to prevent flow into the casing.

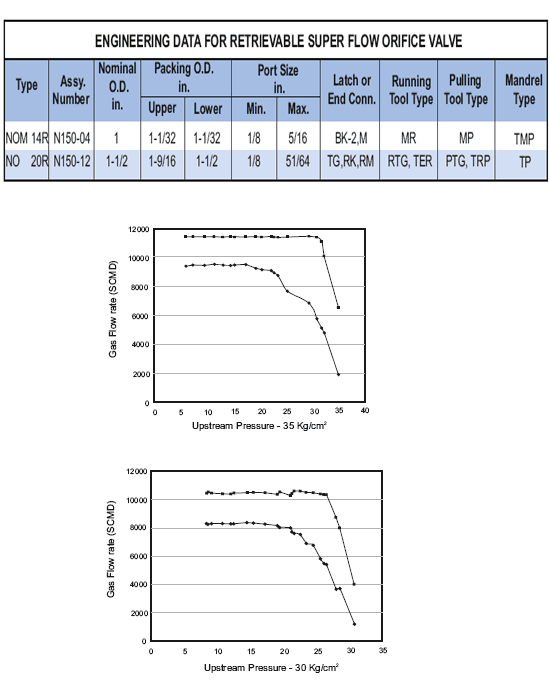

PARVEEN has successfully developed after conducting extensive in-house research the Super Flow Orifice Valve which is one step ahead of Conventional Orifice Valves available in the market. Its performance is dynamically tested by Institute of Oil & Gas Production Technology, ONGCL, Panvel, Mumbai, India.Flow Performance Curve of NOM – 14R Orifice Valve (Port – 12/64”) against different Upstream 2 2 Pressures i.e. 30 Kg/cm & 35 Kg/cm are depicted below and comparison with Conventional Square Edge Orifice Valve are also shown below.

ANALYSIS OF RESULTS

1) The Critical Flow rate was achieved at approx 0.878-0.879 pressure ratio of Down Stream Pressure to Upstream Pressure i.e. at a pressure differential of 12% compared to almost 50% in case of a Standard Orifice in a Conventional Orifice Valve.

2) The Actual Critical Flow rates obtained through the testing were approximately 20% higher than the calculated theoretical flow rates.

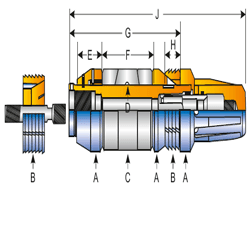

ENGINEERING DATA FOR RETRIEVABLE SUPER FLOW ORIFICE VALVE