Valves are the basic fluid flow control device used in the industrial process control area. There is a wide variety of valves available today based on the different needs of the people. Howbeit, picking the correct type of valve is important for your system’s performance, it’s efficiency and longevity. Each type of valve has different functions suitable for specific applications.

A few of the most essential features that decide a valve’s suitability for a particular application include how the materials used to interact with the specific substance. It is needed to know how the substance is converted, how much amount of it is used and the desired flow rate and also the overall mechanical design of the system.

What are valves generally used for?

Valves are normally used to start, stop, throttle, redirect the flow of the fluid. It is also used in order to prevent fluid flow from going in an unwanted path. The industrial flow control valve types are usually classified according to the structure or the arrangement within the valve body that allows the obstruction to fluid flow.

Few of the common valves are butterfly, gate, glode, ball and plug. Definitely there are various other types as well. However, let’s take a look at one of the oldest valves types that is plug valves.

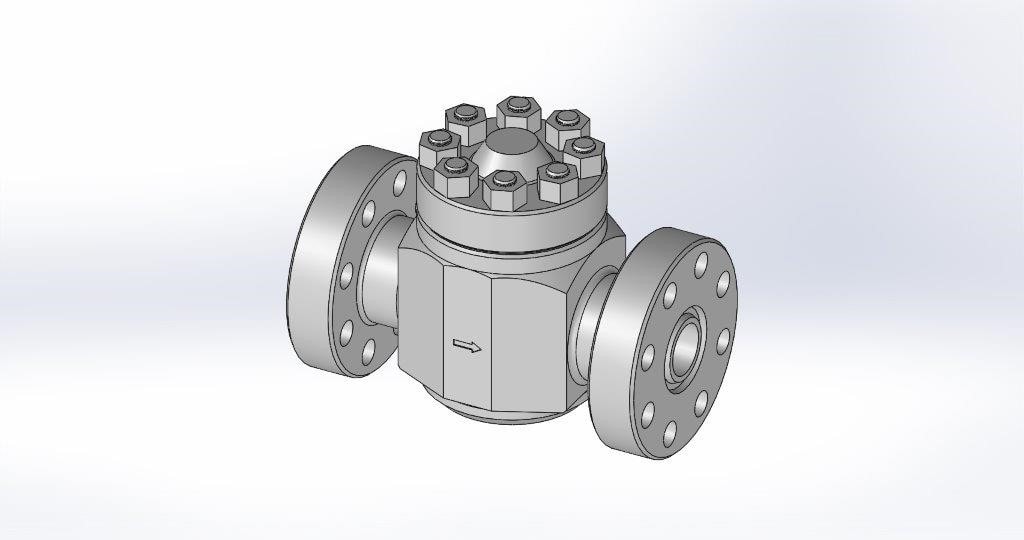

Plug Valves

The “plug” in a plug valve is the position in the flow path in the valve body which is whirled through a stem extending to the exterior of the body.

The cylindrical or conically tapered plug in a plug valve carries one or more hollow passageways running sideways in its width.

When the handle of the valve is set to the off position the plug is turned so that the wellheads are blocked off and pass through the valve is restricted.

Based on the precise models material make-up, plug valves can be utilized for a broad range of applications including the isolation of sections of pipeline bearing neutral or corrosive fluids, slurry, and neutral or corrosive gases.

This valve is to that of ball and butterfly valves, with its circulating movement of 90 degrees from the fully open to the closed positions. Plugs are commonly tapered toward the base and are fixed to a seating surface in the valve body cavity.

An opening by the plug, the port, can be formed to give a particular flow characteristic. There are a variety of alternatives to the basic plug valve which may make it worthy for particular applications. One well-known variant is the lined plug valve, with a centre lining of material convenient to give a measure of corrosion resistance for special media applications.

Some advantages of Plug Valve:

- It’s a 90-degree rotation from open to close supplies speedy rotation.

- The design is simple and easy which employs a low part count.

- Normally, it is low resistance to flow when fully open.

- Through a proper operation, it is well suited for frequent operation.

- The availability of corrosion-resistant liner may give comparative cost savings as such a valve body can be made of less expensive material.

- The valve is serviceable at one place.

- Authentic leak-tight service due to tapered plug wedging action which replaceable sleeve and injection of lubricant in few alternatives.

Plug valves have a quarter-turn operation, plugs are tapered or parallel plugs, and are fit for most on-off clean process and utility services, including non-abrasive slurries.

They have straight through forms typical of the sliding order.

They have straight through forms typical of the sliding order.

The limitations of the basic plug cock are two-fold.

Firstly, its fast action can direct to a water hammer on hydraulic installation when it is stopped too soon. Moreover, it is hard to mix the tight shut-off with quick of operation.

In a nutshell,

If you are looking for a specific type of valve that matches according to your needs, you can get in touch with Parveen. We will help you get the best suitable product, based on our expertise and knowledge experience while providing you the additional input needed to make sure you picked the best choice for your project.