Well Control Valves are used with Well control equipment for use in Drilling & Work over operation. These are used to isolate, to guide, direct and control the flow of oil & gas coming from the oil well.

Well Control Valves are used with Well control equipment for use in Drilling & Work over operation. These are used to isolate, to guide, direct and control the flow of oil & gas coming from the oil well.

GENERAL REQUIREMNET:

Well control valves are generally manufactured as per API-6A standards, besides each major oil company like Saudi Aramco, Shell & Exxon have their own standards which should also be compiled at the time of manufacturing of the WCV.

TYPES OF VALVES:

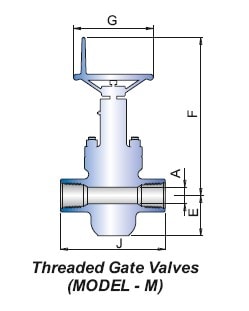

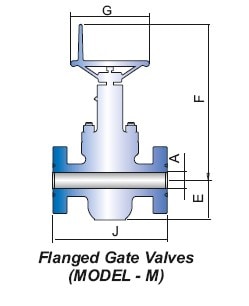

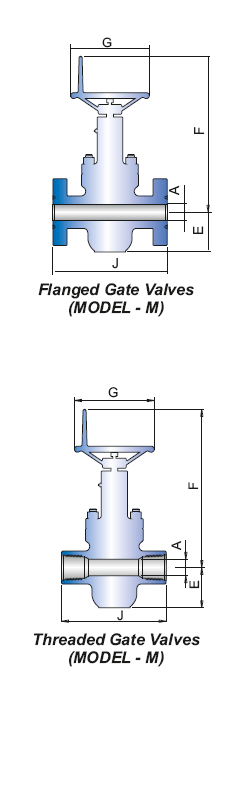

GATE VALVES:

These valves are primarily designed to start or stop a flow when a straight-line flow of fluid with minimum restriction is required. Gate valves are widely used and are suitable for both above and underground installation. These are designed to provide a fully open or fully closed service. These are fitted as isolating valves and should not be used as regulating valves. When operating the valve stem, it either moves up or downwards on the thread of the stem. Gate valves lead to a minimum pressure loss of the fluid. When it is open, there is no obstruction in the flowing path of the liquid, which results in low-pressure drop.

The significant components of gate valves are body, stem, gate, bonnet and sometimes actuator. The operation of gate valves is effortless. When the hand wheel or steering is turned, it rotates the stem, which passes the movement vertically to the gate via threads. Gate valve is also considered a multi-turn valve, as it takes several 360-degree turn to close and open the gate. When the gate is lifted, the oil or gas seamlessly flows, and when the wheel is rotated to close the gate, it seals the bore resulting full closure of the gate valve.

The Gate Valves are available meeting Aramco or SHELL specification for Drilling and work over well control in all popular bore sizes, pressure rating from 2000 PSI to 15000 PSI, temperature class form 0° F to 350° F, PSL 1-PSL 4, PR-2F, different material class, H2S and Standard service as per API-6A and NACE MR-0175, Forged steel Body &Bonnet for durability and integrity, Inconel Inlaid Ring Groove, Spring loaded lip seal, internal pressure containing parts with hard face and studs and nuts are as per API 20E.

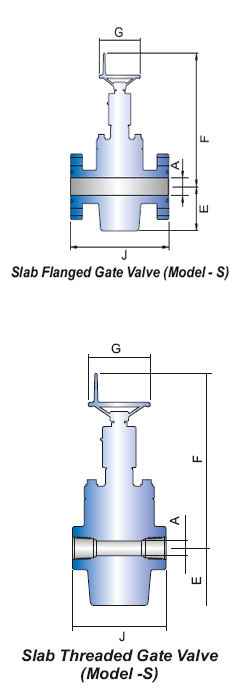

Types of Gate Valve:

Slab type: These types of valves are Bi-directional slab gate type with pressure actuated seat. It offers tight, reliable shut off in Oil and Gas service. Slab type gate valves featured with:

Features:

- Full Bore through conduit

Bleed and block mechanism

- Long life floating seat with self-relief function

- Metal to Metal sealing mechanism

- Metal To Metal stem back seat

- Heavy duty bearing for low torque and easy operation

- Non-rising stem.

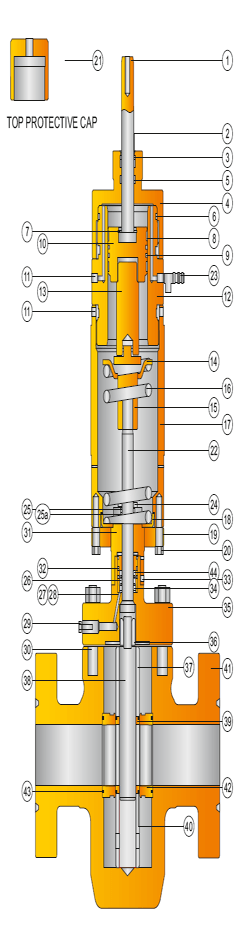

Double Acting –Balance Stem Hydraulic Actuating Gate Valve (HCR VALVE):

The Hydraulic Double Acting Actuating gate valves are used where complete control of the gate valve position is required. These valves are suitable for well testing, high pressure drilling and production accompanied with sour gas or / and sand.

Surface Safety Valve (SSV): The actuator is a fail close hydraulic actuator. The actuator is operated by hydraulic pressure applied through a static piston in translating cylinder. The cylinder actuated by hydraulic pressure, compresses the spring by a upper spring retainer plate and directs the bonnet stem and gate into the open position. Should the hydraulic pressure within cylinder /piston be vented, the spring arrangement ensures an instantaneous valve closure regardless of line pressure.

Spring arrangement, piston and hydraulic cylinder are assembled in a single package enclosed in housing by dual spring plates positioned within a flange and a location shoulder. The actuator assembly is easily removable from the valve for maintenance, actuator replacement or transportation. Hexagonal screws on the lower plate and a threaded connection between the travelling cylinder and stem, keep the actuator connected to the valve.

Only the wrench is required to remove the actuator from the valve.

ESD Control Panels may be used for actuators.

PNEUMATIC DIAPHRAGM GATE VALVE: Pneumatic Diaphragm Gate Valve are having less friction, long life and dependable sealing. When fluid pressure in pipeline has some trouble, it could auto off main valve while controlling system pressure bleeds. This valve has been installed with manual pressure relief device, over pressure auto protector and manual operated device.

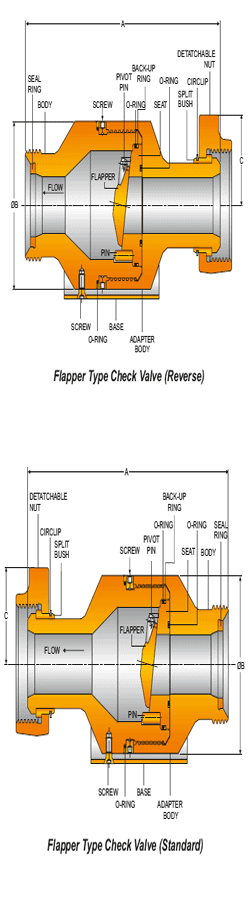

CHECK VALVE:

A check valve is a unidirectional valve and usually installed in high pressure pipelines for preventing fluid flowing back in well service operation. This valve allows fluids to flow in one direction but closes automatically to prevent flow in the opposite direction (backflow). Check valve is lift check type. The valve may be full opening or reduced opening & used to permit fluid flow in only one direction. All full opening valves have round passageways through the body & seat. Check valve creates the metal to metal seal by the pressure of the medium; more the pressure is better the sealing effect. Valve body is machined from alloy steel forging with a stronger physical properties & reliable performance.

FEATURES

- It has uni direction flow.

- It works as a NRV.

- Valve core is spring loaded.

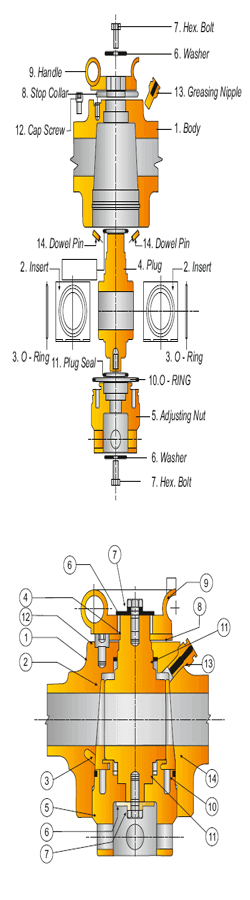

PLUG VALVE:

A Plug Valve is an industrial purpose valve which is used to control the flow of fluid in pipelines or into any processing units. These valves have plugs which are either conical or cylindrical tapered and can be rotated inside the valve body either with the help of a hand wheel or motor actuated.

Features:

- The valve bodies are made from alloy steel forgings which are designed to variety of end connections to be integrally machined.

- The plugs and inserts are designed to resist abrasion and corrosion.

- The valves can be easily adopted for hydraulic or pneumatic actuation. These configurations are designed for integration with complete manifold systems.

- 3” & 4” Fig-1502 Plug Valves can be supplied with gear operated handle.